Processing and Installation of Aluminum Composite Panels

Alushine aluminum composite panels are easily shaped into curves, curve corners, routing, grooving, punching, and bending according to different building design requirements in order to make the structure more attractive.

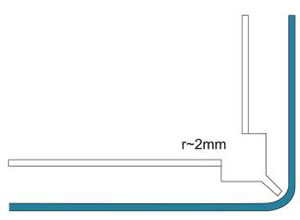

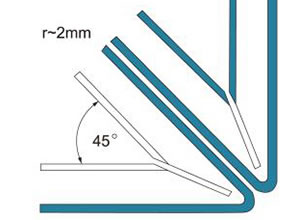

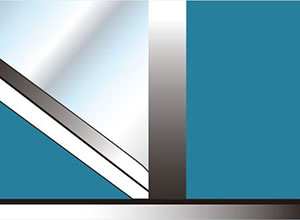

Routing and Folding Techniques

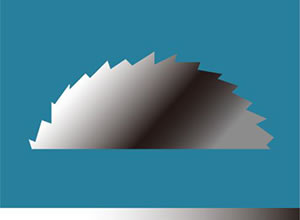

Alushine panels are easily formed into a designed shape. The reverse side is first routed and panel folded. Routing is then performed using one of the tools shown below.

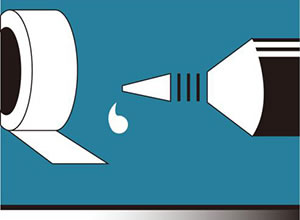

- A disk cutter with disk appropriate for the angle

-

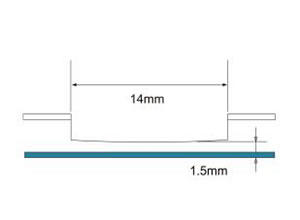

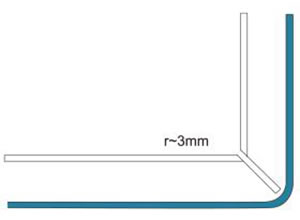

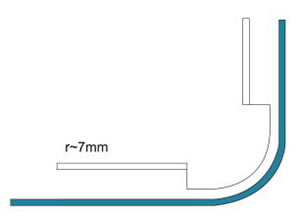

Bending by cold

- The common router with appropriate "bit"

- A typical bench saw etc.

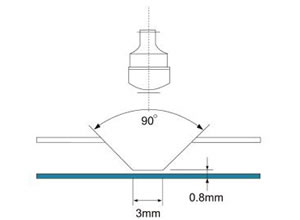

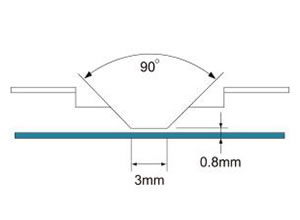

- Groove 90° (V-shape) for folding up to 90°

- Not suitable for Alushine rectangular groove for folding up to 150° depends on the panel thickness

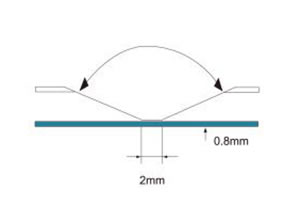

- Another way to folding up to 90°

- Groove 135° (V-shape) for folding up the 135°

Processing method

- Fabrication: Cutting

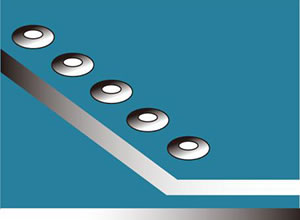

- Fabrication: Punching

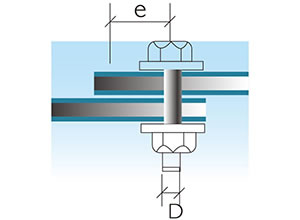

- Fabrication: Bolting

- Fabrication: Welding

- Fabrication: Shearing

- Fabrication: Glueing